How do Water Pressure Pumps Work?

- Home

- >

- Help & Advice Centre

- >

- How Does a Water Pressure Pump Work?

Water pressure pumps are responsible for increasing the pressure and water flow rate in your home. Manufacturers label their pumps as a ‘booster pump’, and the devices come in all shapes and sizes.

Here, we explain how water pressure pumps work, what to look out for if you have low water pressure, and when to call in the experts should you suspect there’s an issue with your pump.

Page Contents:

Whether it’s your shower, tap, or the hosepipe in the garden, many of us have experienced slow-running water. While you might not give it much thought, it’s a telltale sign of low water pressure in your home. But don’t worry, there are ways to improve your water pressure.

A booster pump can increase mains water pressure throughout your home, from boosting a single tap to a full inline mains booster pump for the entire house. Booster pumps are available to address any low-water issues.

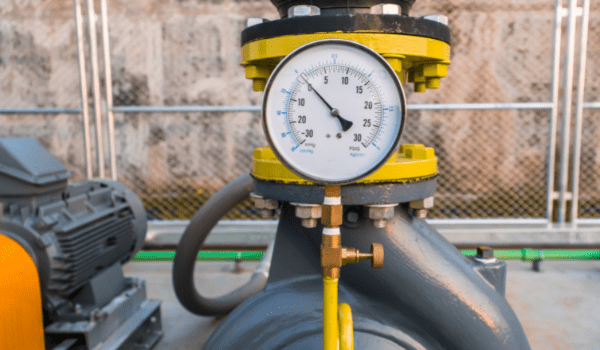

Water pressure pumps have four main components: motor, impellers, inlet and outlet, and a pressure or flow sensor. Water is moved by the impeller, driven by the motor, through the inlet and out through the outlet, increasing water pressure. The sensor monitors outlet pressure and signals the pump to adjust its speed to keep a set pressure level.

The pumps can be operated manually or by an on-demand system, all specifically designed to work in harmony.

A water pressure pump is designed to improve water flow and maintain consistent pressure across various applications. It is a versatile solution suitable for both residential and commercial use. Below, we outline its key functions:

Enhance water pressure for showers, washing machines, toilets, and other household appliances. By ensuring steady and adequate pressure, they enhance performance and help maintain user comfort.

Deliver reliable water pressure when transferring stored rainwater to taps, hoses, or other outlets, making it an essential component of sustainable water management.

Provide a steady water supply for irrigation systems. Whether for gardens, lawns, or agricultural fields, they ensure adequate pressure to operate automated sprinklers or irrigation systems effectively.

By addressing a range of requirements, water pressure pumps help improve water distribution and support environmentally conscious practices such as rainwater harvesting and automated irrigation.

If you have a water pressure pump installed in your home, having no running water or low water pressure is a concrete sign that there’s an issue.

However, other problems could arise that are important to be aware of, so you can catch the faults early on:

Sometimes, the problem is as simple as your valves only being partly open. Make sure the shutoff valves near your water meter are completely open. Once they are fully open, check your water pressure with a gauge.

If you don’t have a water pressure gauge, you can get an empty one-litre bottle or jug and time how long it takes to fill it with your tap. The ideal time is between 4 and 6 seconds, as this should mean that your flow rate is between 10 and 15 litres a minute. If it takes longer than six seconds to fill, there may be an issue, as this indicates a low water flow rate.

Start by ensuring the electrical power is switched on and properly reaching both the pump control switch and the pump itself. This is a key step to rule out any power-related issues.

If the problem isn’t electrical, check the water pressure gauge on the tank. Look at the pressure reading; if it shows a value below the cut-in pressure (the minimum pressure level that triggers the pump to activate), but the pump isn’t switching on, the issue is likely due to a faulty or worn pressure switch or gauge. These components should be inspected and replaced to restore proper operation.

If your water booster pump is making more noise than usual, one or more bearings are likely worn.

A squeaking or clicking sound coming from the bearings is a warning sign that they are wearing and on the verge of breaking. Worn or noisy bearings should be replaced immediately to prevent further damage to any related components.

Another issue that could lead to noise is debris caught in the system, which will need to be cleared out.

The pipework attached to your pump may have worn down. To fix this leak, the section of affected pipework will need to be replaced.

In some cases, the booster pump will need to be replaced entirely. In these circumstances, switch off your water supply and call our experts here at Metro Plumb.

Metro Plumb experts are fully trained in the maintenance and repair of mains water booster pumps, with bespoke packaged booster sets available. We can provide the design, supply, and installation services of a new booster if you’re building an extension or changing the use of your building.

Don’t hesitate to get in touch by calling our 24/7/365 helpline on 0808 250 9949.

Centrifugal pumps are widely used in residential, agricultural, and industrial settings because they are simple, cost-effective, and efficient for moving large volumes of water.

A centrifugal pump moves water using a rotating impeller, creating pressure that pushes water through a connected system. It’s commonly used for irrigation, residential plumbing, and industrial applications.

Water pumps, while highly beneficial, can have some drawbacks. They consume energy, which may increase costs, and some models can produce noise during operation. Over time, components may wear, leading to potential issues, including leaks or clogged intakes. Regular maintenance is essential to ensure reliable performance and to address wear or part replacements as needed. These factors vary depending on the type of pump, the design, and its usage. Selecting the right pump and ensuring proper installation and upkeep can minimise these concerns and maintain efficiency.

Most water pumps push water rather than pull. They are designed to create pressure that moves water through pipes rather than drawing it over long distances.

Mechanical pumps are driven by engines, making them ideal for vehicles. Electric pumps are more efficient and cost-effective for household and industrial use, offering better control over water flow.